How Can Modular Buildings Revolutionize Modern Construction?

2025-10-21

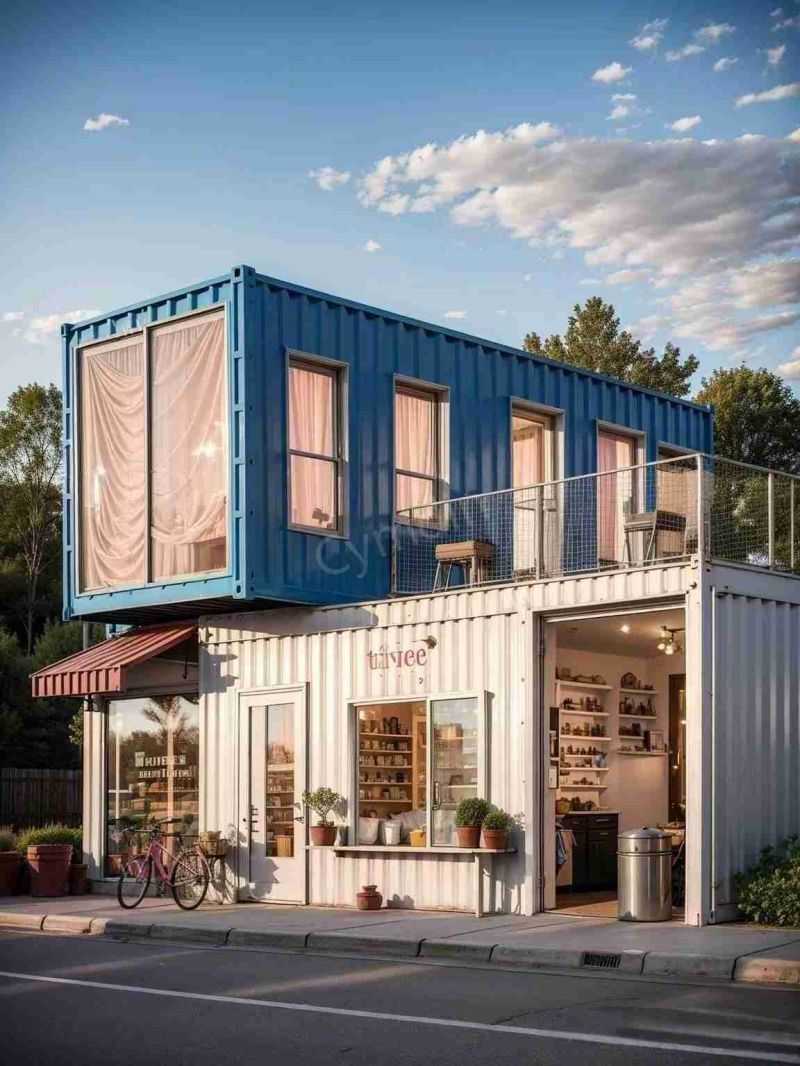

Modular buildings are redefining the construction industry by offering speed, flexibility, and cost-efficiency that traditional methods cannot match. These structures are built in sections, or modules, in a factory-controlled environment, then transported and assembled on-site. This method ensures precision, reduces waste, and allows projects to be completed significantly faster.

Modular buildings cater to a wide range of applications, including residential complexes, offices, schools, healthcare facilities, and commercial spaces. Their adaptability allows them to meet strict design specifications while maintaining sustainability standards. Below is a detailed overview of key product parameters that highlight their engineering precision and versatility:

| Parameter | Specification |

|---|---|

| Material | High-grade steel frame, reinforced concrete panels |

| Module Size | Standard: 3m x 6m, customizable up to 6m x 12m |

| Wall Insulation | Rock wool or polyurethane foam (thermal & acoustic) |

| Floor Load Capacity | 500 kg/m² (residential), 1000 kg/m² (commercial) |

| Fire Resistance | Up to 2 hours |

| Sound Insulation | STC 50+ |

| Assembly Time | 1 module per 4–6 hours on-site |

| Transportation | Flat-packed modules for easy logistics |

| Sustainability | Recyclable materials, minimal waste |

| Customization Options | Facade finishes, interior layouts, modular extensions |

This table underscores the technical robustness and adaptability of modular building systems. Every module is precision-engineered to comply with local building codes, ensuring safety, reliability, and long-term durability.

What Are the Key Advantages of Modular Buildings Over Traditional Construction?

The primary advantages of modular buildings lie in their efficiency, cost-effectiveness, and environmental sustainability. Unlike conventional construction, which can span months or years, modular construction drastically reduces project timelines because site preparation and module fabrication occur simultaneously. This parallel workflow ensures rapid deployment without compromising quality.

Cost Efficiency: Modular construction minimizes labor costs, reduces site disruptions, and lowers material wastage. Factory-controlled conditions reduce errors, which translates to fewer delays and additional expenses.

Sustainability: Modular buildings generate significantly less construction waste compared to traditional methods. Materials are often recycled, and energy-efficient manufacturing processes lower carbon emissions. Furthermore, modules can be disassembled and relocated, extending their lifespan and reducing environmental impact.

Flexibility and Scalability: Modular buildings are highly adaptable, making them ideal for projects with changing requirements. They can be expanded vertically or horizontally, reconfigured internally, or relocated entirely with minimal disruption.

Safety and Quality Assurance: The controlled factory environment ensures consistent quality checks, structural integrity, and adherence to building standards. Modules are designed to endure transportation stress and on-site assembly conditions.

Future-Proofing: With urbanization accelerating globally, modular buildings offer scalable solutions for high-density areas, temporary housing needs, emergency facilities, and commercial expansions. This trend is expected to grow, making modular technology a vital component of modern construction planning.

How Do Modular Buildings Work and What Are Their Typical Applications?

Understanding the mechanics of modular construction is essential to appreciating its efficiency and flexibility. Modular buildings are designed and fabricated in sections in a factory, using advanced machinery and precision tools. Each module is complete with structural, mechanical, electrical, and plumbing systems, often referred to as MEP integration. Once modules pass quality inspection, they are transported to the construction site using flatbed trucks or cranes. On-site assembly is rapid, and modules are joined together using secure interlocking connections.

Steps in Modular Construction:

-

Design and Planning: Architects and engineers design modules based on project requirements. 3D modeling ensures precise alignment and compatibility.

-

Factory Fabrication: Modules are built under controlled conditions with pre-installed wiring, plumbing, insulation, and finishes.

-

Transportation: Completed modules are transported using specialized trucks to minimize damage.

-

On-Site Assembly: Modules are positioned, aligned, and connected. Finishing touches such as exterior cladding, landscaping, and utilities finalization are completed rapidly.

-

Inspection and Handover: Each building undergoes final inspections for structural integrity, safety, and code compliance.

Common Applications:

-

Residential Housing: Rapid deployment of apartment complexes, multi-family housing, and single-family units.

-

Healthcare Facilities: Clinics, hospitals, and quarantine units that require fast construction.

-

Educational Buildings: Schools, classrooms, and university dormitories with flexible layouts.

-

Commercial Offices: Co-working spaces, retail stores, and temporary offices.

-

Emergency and Temporary Structures: Disaster relief housing, temporary shelters, and pop-up facilities.

Modular buildings’ ability to meet diverse requirements while maintaining quality and speed has made them an increasingly preferred choice in urban planning, corporate projects, and humanitarian efforts.

Why Are Modular Buildings the Future of Sustainable Construction?

Sustainability is no longer optional in the construction industry—it is a requirement. Modular buildings directly address environmental challenges through reduced resource consumption, lower carbon emissions, and minimal construction waste. Factory-based fabrication ensures precise material usage, while modules can be disassembled, reused, or recycled.

Innovation in Materials: Modern modular buildings use eco-friendly materials such as recycled steel, low-VOC paints, and energy-efficient insulation, which reduce the building’s environmental footprint.

Energy Efficiency: Modular buildings can integrate solar panels, smart HVAC systems, and advanced insulation, achieving high energy-efficiency ratings.

Urban Adaptability: As cities face space constraints, modular buildings offer vertical and horizontal scalability. They can transform underutilized plots into functional living or commercial spaces.

Disaster Resilience: Modular construction allows quick deployment of resilient structures capable of withstanding extreme weather conditions, earthquakes, and flooding. This adaptability enhances community preparedness in vulnerable regions.

Technological Integration: The future of modular construction lies in automation, AI-assisted design, and BIM (Building Information Modeling), which optimize workflows, reduce errors, and provide actionable insights throughout the building lifecycle.

Frequently Asked Questions About Modular Buildings

Q1: How long does it take to construct a modular building compared to traditional methods?

A1: Modular buildings can be completed in 30–50% less time than traditional construction. Fabrication occurs simultaneously with site preparation, allowing rapid on-site assembly. Depending on the project size, a mid-rise office or residential building can be operational within weeks, rather than months.

Q2: Are modular buildings durable and safe?

A2: Yes. Modular buildings meet the same building codes and safety standards as traditional structures. High-grade steel frames, reinforced concrete panels, and fire-resistant materials ensure structural integrity. Factory-controlled assembly and quality inspections minimize defects and ensure long-term durability.

Modular buildings are revolutionizing the construction industry by providing faster, cost-effective, and sustainable alternatives to traditional methods. With applications spanning residential, commercial, healthcare, and emergency projects, their adaptability and scalability make them a preferred choice for modern urban planning. Innovations in materials, energy efficiency, and modular design continue to enhance their appeal, establishing them as a cornerstone of future construction trends.

Cymdin specializes in delivering high-quality modular building solutions that integrate advanced engineering, sustainability, and rapid deployment. For tailored project solutions and expert guidance on modular construction, contact us today to explore how Cymdin can transform your next construction project.